Designation and Standards

Standard Designation: TU2 (China GB/T 5231-2012)

International Equivalent Grades:

ASTM B152: C10100 (Oxygen-Free Copper)

EN 13601: Cu-OFE (Oxygen-Free Electrolytic Copper)

Product Features

Ultra-High Purity: Copper content ≥ 99.95%, with minimal impurities and oxygen content ≤ 0.002%.

Excellent Conductivity and Thermal Conductivity: Conductivity ≥ 101% IACS, Thermal Conductivity ≥ 397 W/(m·K).

No Hydrogen Embrittlement Risk: Low oxygen content prevents embrittlement in high-temperature reducing environments.

Superior Workability: Excellent ductility, suitable for stamping, drawing, and welding processes.

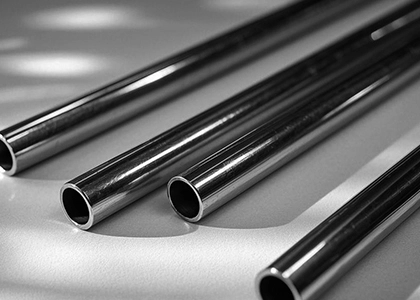

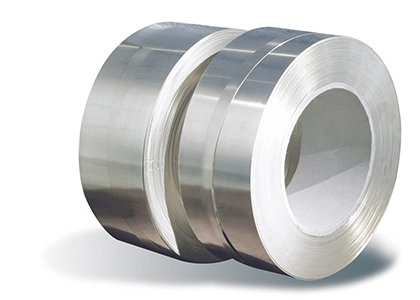

Common Product Forms and Dimensions

| Product Form | Dimension Range | Surface Condition |

| Strip | Thickness: 5-50mm; Width: 20-300mm; Length: ≤6m | Smooth/1/2Hard |

| Plate | Thickness: 0.5-50mm; Width: 100-2000mm | Rolled/Polished |

| Tube | Outer Diameter: 3-200mm; Wall Thickness: 0.5-15mm | Y/M (Annealed) |

| Wire | Diameter: 0.1-10mm; Coil Weight: 50-500kg | Bright/Tin-Plated |

Chemical Composition

| Element | Cu | O | P | S | Total Impurities |

| Content | ≥99.95% | ≤0.002% | ≤0.001% | ≤0.002% | ≤0.05% |

Physical Properties

| Property | Value | Test Standard |

| Density | 8.96 g/cm³ | GB/T 3850 |

| Melting Point | 1083°C | GB/T 232 |

| Conductivity (20°C) | 101-103% IACS | GB/T 3048.2 |

| Thermal Conductivity (20°C) | 397-401 W/(m·K) | ASTM E1461 |

| Thermal Expansion Coefficient | 16.5×10⁻⁶/°C (20-100°C) | GB/T 4339 |

Mechanical Properties (Annealed State)

| Property | Value | Test Standard |

| Tensile Strength | 200-250 MPa | GB/T 228.1 |

| Yield Strength | 60-80 MPa | GB/T 228.1 |

| Elongation (δ) | ≥35% | GB/T 228.1 |

| Hardness (HV) | 40-60 | GB/T 4340.1 |

| Elastic Modulus | 110-130 GPa | GB/T 22315 |

Core Advantages

Purity Assurance: Ultra-low impurity content ensures stable electrochemical performance.

High-Temperature Stability: Suitable for vacuum or noble gas environments (e.g., semiconductor manufacturing).

Corrosion Resistance: Excellent oxidation resistance in dry, sulfur-free environments.

Processing Flexibility: Supports precision etching, laser cutting, and other complex processes.

Product Applications

| Industry | Typical Applications | Key Requirements |

| Electronics | Integrated circuit lead frames, high-frequency transformer windings | High conductivity, low signal loss |

| Energy Equipment | Solar cell conductors, nuclear power plant cooling tubes | Radiation resistance, long-term thermal stability |

| Automotive | EV cooling plates, high-voltage connectors | High thermal conductivity, vibration fatigue resistance |

| Aerospace | Rocket engine liners, thermal management systems | High-temperature oxidation resistance, lightweight design |

Processing Notes

Cold Working: Intermediate annealing (650-800°C under noble gases) is required if deformation exceeds 30%.

Welding: Preferably use TIG welding (argon purity ≥ 99.99%) to avoid porosity and oxidation.

Cutting: Recommend low-speed, high-feed cutting with sulfurized cutting oil to reduce tool wear.

Surface Treatment:

Short-term Anti-Oxidation: Apply Benzotriazole (BTA) corrosion inhibitor.

Long-term Protection: Nickel electro plating (thickness ≥ 5μm) or hot dip tinning.

Key Application Scenarios

High-Precision Heat Sinks: 5G base station chip heat sinks, IGBT module substrates.

Vacuum Equipment Components: Coating machine targets, particle accelerator conductive cavities.

Superconducting Material Carriers: Low-temperature superconducting cable support frames (used in liquid nitrogen environments).

Frequently Asked Questions

Q1: Can TU2 copper replace T2 copper?

TU2 is required for high conductivity/thermal conductivity or vacuum environments, while T2 can be used for cost savings in conventional applications.

Q2: How to check if oxygen content is compliant?

Oxygen content is professionally tested using Noble Gas Fusion-Infrared Absorption Method (GB/T 5121.7).

Q3: How to deal with surface oxidation after long-term storage?

Light oxidation can be removed with 5% citric acid solution; severe oxidation requires mechanical polishing and passivation treatment.

Standards Reference

| Standard Type | Standard Number | Scope |

| Chinese Standard | GB/T 5231-2012 | Chemical composition, grade definition |

| American Standard | ASTM B152-20 | Dimensions and tolerances for oxygen-free copper products |

| European Standard | EN 13601:2013 | Conductivity and mechanical properties testing methods |

| International Standard | ISO 1337:2020 | Hydrogen embrittlement susceptibility evaluation for high-purity copper |

Additional Notes

Environmental Compliance: Compliant with RoHS 2.0 (Heavy Metal Limits) and REACH SVHC regulations.

Customization Services: Supports non-standard dimensions, pre-coating (tin/silver/nickel), and other special requirements.

For additional performance curves or application examples, please contact technical support!

English

English 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano العربية

العربية tiếng việt

tiếng việt Türkçe

Türkçe ไทย

ไทย 中文

中文